Fire Extinguishers, where would we be without them? They are an important piece of Health and Safety equipment, to keep our schools, homes businesses and vehicles safe. But what are the different types and what are they used for? In this guide, I will take you through each category extinguisher, what’s in it and what it is used for.

Let’s start with the basics. A Fire Extinguisher is basically a canister, which contains the extinguishing agent in one capsule and either compressed air or another compressed gas, such as Nitrogen in another capsule. (Except C02) Once you have removed the safety tag, pulled the pin and squeezed the handles, the compressed gas or air, will spray the extinguishing agent at high pressure, through the nozzle on the neck of the extinguisher.

OK, now we know how they work, let’s look at the different types of extinguisher.

Water

Water Fire Extinguishers are just that… More or less, the same water that comes from the tap. Water cools burning material and is very effective against fires in furniture, fabrics, etc. (including deep-seated fires). Water-based extinguishers cannot be used safely on energized electrical fires or flammable liquid fires.

These extinguishers are used on organic materials, such as wood, paper and fabrics.

Powder

This is a powder-based agent that extinguishes by separating the four parts of the fire tetrahedron. It prevents the chemical reactions involving heat, fuel, and oxygen, thus extinguishing the fire. During combustion, the fuel breaks down into free radicals, which are highly reactive fragments of molecules that react with oxygen. The substances in dry chemical extinguishers can stop this process.

These extinguishers are used on organic materials, such as fabrics, paper and wood) paints, flammable gasses, (EG: Butane and Methane) flammable materials, such as Magnesium or Lithium and electrical equipment that is not energised.

Foam

Foam Extinguishers are applied to fuel fires as either an aspirated (mixed and expanded with air in a branch pipe) or non aspirated form to create a frothy blanket or seal over the fuel, preventing oxygen reaching it. Unlike powder, foam can be used to progressively extinguish fires without flashback and also cannot be inhaled, thus preventing breathing difficulties if breathed in.

These extinguishers are used on organic materials (wood, paper and fabrics) only

Carbon Dioxide (C02)

These extinguish fire by displacing oxygen CO2 or inert gases), removing heat from the combustion zone They are referred to as clean agents because they do not leave any residue after discharge, which is ideal for protecting sensitive electronics, aircraft, armored vehicles and archival storage, museums, and valuable documents. This is often seen in Server Rooms, Plant Rooms and other areas, where there is sensitive equipment. It is normally connected to a Fire Suppression System.

The extinguisher discharge the clean agent through and hose and out through a horn at the end of the hose. Because CO2 is extremely cold, users are told not to hold the horn, when discharging.

These extinguishers can be used on flammable liquids and energised electrical fires.

Wet Chemical

These extinguishers are more often than none, seen in Commercial Kitchens, on as Fire Bottles on Diesel Trains. (On the underside of the train)

Wet chemical (Potassium Acetate, Potassium Carbonate, or Potassium Citrate, extinguishes the fire by forming an air-excluding soapy foam blanket over the burning oil through the chemical process of saponification (a base reacting with a fat to form a soap) and by the water content cooling the oil below its ignition temperature.

Sometimes, the extinguishers may be in the form of a Fire Bottle, for automatic or manual discharge. This is common where there are Deep Fat Fryers in a Commercial Kitchen, (Activated, by pulling the pin out of it’s casing) or mounted to the Chassis of a Diesel Train, which can be automatically discharged by the Train Management System, or manually activated by pulling a pin. This type of equipment can be classed as Fire Suppression, which is a type of sprinkler system, which uses a wet or dry chemical, to extinguish a fire.

These extinguishers can be used on organic materials and cooking oils.

How to use an extinguisher

Fire extinguishers should only be used if the fire is small and that it will not put YOU or anyone else in IMMEDIATE DANGER. If you don’t feel that you can tackle the fire yourself, or there is a lot of smoke, Evacuate the building and call the Fire Brigade, by dialing 999.

All extinguisher have the same operating instructions, using the “P.A.S.S Protocol”.

- Pull out the Pin that is locking the handles

- Aim at the base of the fire. (This is where the fire is at it’s hottest.)

- Squeeze the handles

- Sweep side to side

The difference between Wet and and Dry Risers

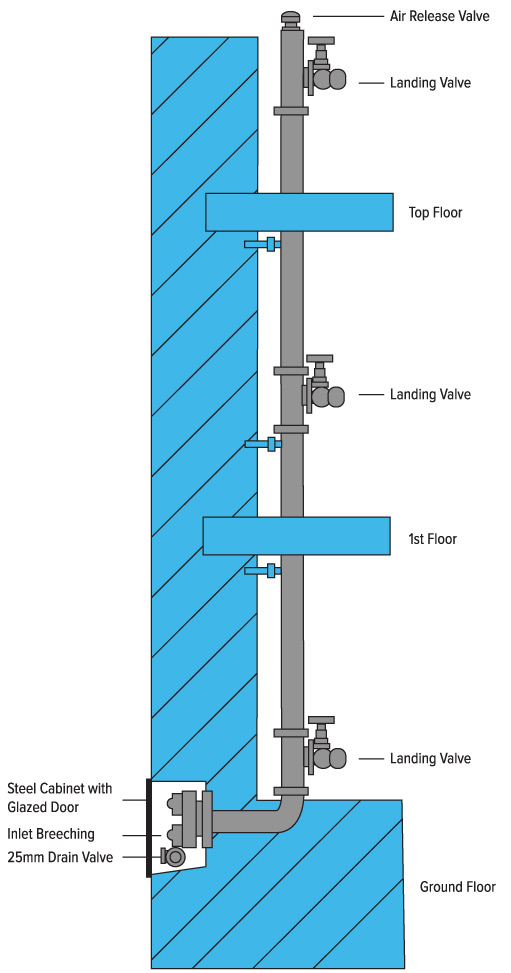

There is one main difference between a Wet and a Dry Riser. One is connected to the mains water supply and is constantly kept at Mains Pressure (Wet Riser) and the other is a empty tank, which is connected by a hose, to a Fire Engine or to a Fire Hydrant.

All Risers have the same principle, regardless if they are wet or dry. The system contains a pipe, which runs up the inside of the building. In most buildings, the connection valve is kept in a cupboard, which requires a Firefighter to break the glass door, to connect the hose. Then, the valve is turned and water will fill the hose. At the very top of the building, there is a Air Valve, to release any air, which has got in the system and could cause a airlock. This could prevent the Riser from working properly.

Wet Risers require mains pressure to work and are normally connected to the mains water, which is fed from the nearest Fire Hydrant. In some buildings, there is a water tank present, which the Wet Riser feeds from. Connecting your Wet Riser to the domestic Water Supply is not practical, as the dimensions of the pipe are too small, to allow enough water to flow through.,

Dry Risers on the other hand, do not require connected to the main supply. However, there may be a nearby Fire Hydrant, which can be connected to the inlet, by Fire Fighters. If there is no hydrant near by, Fire Fighters can connect the other end of the hose to the Fire Engine and use stored water, from the tank on the Fire Engine itself.

In my school, we have mainly Dry Risers, but there are Wet Risers in D Block, which is where the Gym, Swimming Pool, Drama Studio and Dance Studio are.

Before we conclude, I will mention that Fire Sprinkler Systems are a form of Wet Riser, as the system is always pressurized and is activated when the heat builds to a dangerous level, which causes the vapour in the glass plug (Which is connected to the sprinkler head) to evaporate. This causes the plug to shatter, allowing water to flow.

Dry Systems are usually used in Fire Suppression Systems, in Server Rooms and Plant Rooms. This system is similar, except the system is not pressurised and there is no plug on these systems. Once the system detects rising smoke, the system switches off any ventilation systems, sounds an alarm and opens a valve, which allows the dry agent to flow through the sprinklers, at high pressure.